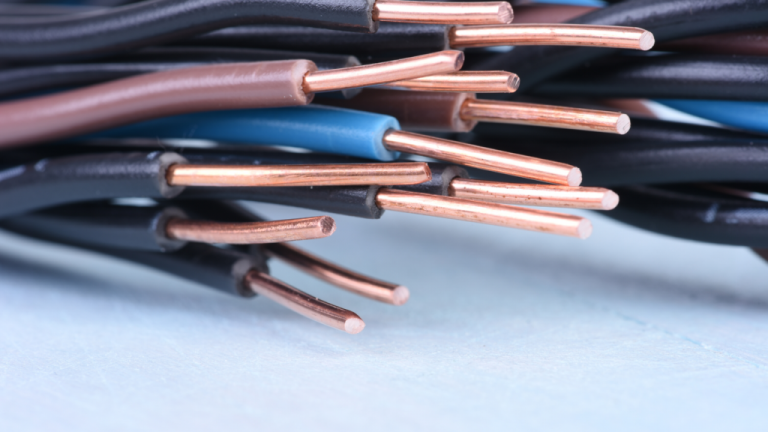

Preparation for connecting cables

Before you start connecting the cables in the junction boxes, you need to know which cables are power (coming from the floor panel), which go to the switch, which to the lamps, which to the sockets, etc. There is a simple way to identify the cables that will be useful in different situations (not only in distribution boxes), and for the realization you will need: pliers for removing insulation (blankers), unimer, regular pencil, insulating tape, marker, etc.

Identifying cables

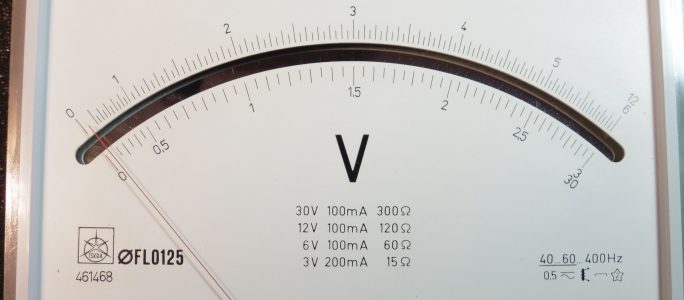

When you have everything you need in preparation for connecting the cables, focus on one junction box. Remove the insulation from the ends of all cable wires in the junction box as well as from the ends of all cables at the floor panel and those in the mounting boxes of sockets, switches or various consumers to which the observed distribution box is closest. Select one of the cables in the junction box. With the naked eye, you can see from which side the individual cable enters the junction box, which will shorten your wandering. The other end of the cable safely ends in a socket, switch, lamp or other consumer located on the other side of the distribution box from which the cable enters it. Between the ends of the cable in the junction box, measure the resistance with a multimeter and connect the wires that are the same color as the ones you are measuring. At the moment when some resistance is the unimeter shows some resistance value (if everything is correct close to zero) you have found your cable.

Connecting cables in junction boxes

There are several ways to connect cables in junction boxes. One possibility is to bend the wires of the selected cable to a specific side (up, down, left, right, at an angle, whatever) and next to the wires, write on the wall where that cable ends. The words/symbols with which you will mark the cable are completely arbitrary and it is best to mark the way that makes the most sense to you because later it will be easier to recognize what you have written. Therefore, the external Another possibility is to tape the wires of the selected cable with insulating tape and let the tape hang from the wires, like a flag. Mark the cable on that part of the tape with a marker. Speaking of marking with a marker, when you find the cable in the floor panel, you should write on it in which distribution box it ends (if it does not go directly to the consumer). You can also do this by writing directly on the cable insulation at the very point where the cable exits the wall, because that part of the insulation will probably not be removed.

Should connecting cables be left to a professional?

Connecting cables Lay people are advised not to get involved in any electrical work. Not only is there a risk of injury, but insurance does not apply to DIY electrical system work. A professional takes care of tasks like connecting cables in no time, and also guarantees the functionality and long life of the cable. So, connecting the cables can be done professionally for relatively little money, and is by no means worth the risk of electric shock or material damage.

Connecting cables Lay people are advised not to get involved in any electrical work. Not only is there a risk of injury, but insurance does not apply to DIY electrical system work. A professional takes care of tasks like connecting cables in no time, and also guarantees the functionality and long life of the cable. So, connecting the cables can be done professionally for relatively little money, and is by no means worth the risk of electric shock or material damage.

Continuation of cables

Since the cables are of limited length, they must be continued at certain intervals. There are two basic actions: continuation of the conductor in the cable and continuation of other parts of the cable (sheath. reinforcement and protective layers). The conductors in the cable can be continued in several ways: by twisting (twisting) conductors, one around the other, soldering, connectors. Twisting the conductors is the simplest way to continue the conductors. First, an insulating tube is put on one of the conductors, then two to three rounds of insulated conductors are twisted. Then about 35 mm of insulation is removed from the conductors and the conductors are twisted all the way. When the twisting is finished, the conductors are shortened to 30 mm. If the conductors are of different diameters, tip soldering is mandatory. After finishing the connection, a protective insulating tube must be pulled over the non-insulated joint. Today, connectors are mostly used to connect conductors. There are two types of connectors: dry and with a special gel mass. Connectors with gel mass are used to connect filled cables, while dry connectors are used for all other cables. The connector has grooves into which a wire with insulation of the incoming line is inserted on the upper side, and the outgoing line on the lower side. When the wires are placed appropriately, two plastic covers are placed on the upper and lower sides of the connector and the connector is pressed with a special press, which completes the process of connecting the conductors.